When you hand over your logo to PROMOXWEAR, you’re not just ordering shirts — you’re asking a team of specialists to turn your brand into wearable art.

From first sketch to final stitch, our process blends technology, craftsmanship, and years of embroidery expertise. Whether it’s a polo, hoodie, hat, or jacket, every piece that leaves our shop represents your business at its very best.

Step 1: Turning Your Logo into a Digital Blueprint

Every design begins with digitizing — the process of converting your logo into a precise stitch map that embroidery machines can read.

Our in-house experts analyze your design, adjusting line thickness, texture, and thread direction so the final piece has depth and clarity. This step makes all the difference between a flat logo and a professional finish.

🎯 Want to see your logo come to life? Contact us and we will send you a quote PROMOXWEAR.com

Step 2: Choosing the Perfect Thread & Color Match

At PROMOXWEAR, we use premium Madeira threads for their strength, color consistency, and sheen. Our library includes hundreds of shades, from bold primaries to soft pastels and metallic finishes.

If you already have brand guidelines, we’ll color-match your embroidery using Pantone references — ensuring your logos look identical across every product, from polos to hats.

🧵 Learn more about our embroidery services.

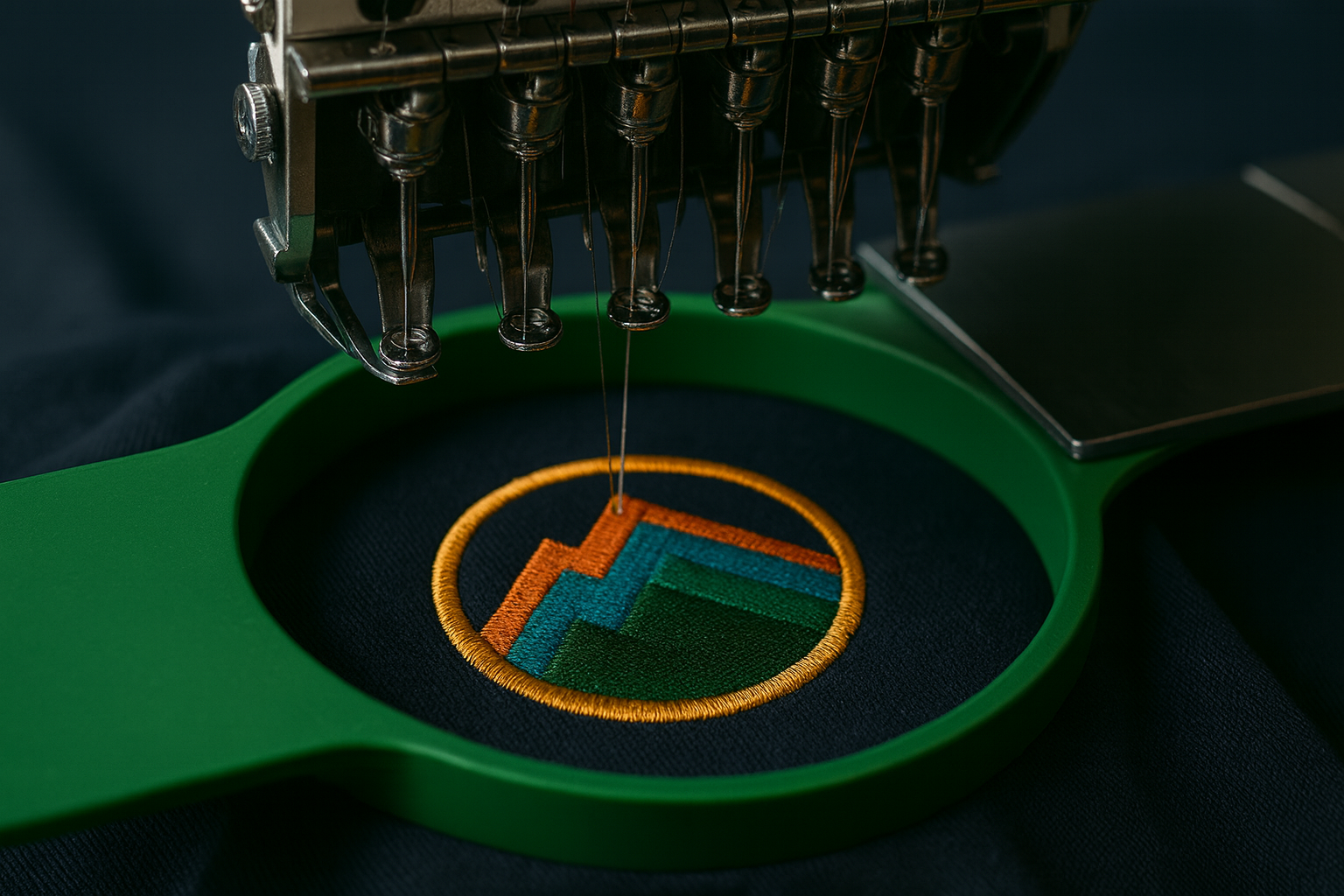

Step 3: Setting Up the Machine

We work only with the best machines on the market - Tajima. It is the industry’s gold standard for precision.

Our team programs the exact stitch sequence and tension settings for your material (cotton, polyester, performance fabric, etc.) to ensure every logo comes out crisp and professional.

Before we begin production, we always run a real sewn-out proof — not a mockup — and email you a high-resolution photo for approval. This ensures zero surprises and 100% satisfaction.

Step 4: The Stitching Process

Once your proof is approved, the stitching begins. Depending on the complexity of the design, a single logo can take anywhere from 5,000 to 25,000 stitches to complete.

We carefully monitor every run to avoid puckering, thread breaks, or color misalignment. PROMOXWEAR’s attention to detail means every logo looks clean, durable, and perfectly balanced — no shortcuts.

💡 Tip: Embroidery isn’t just for polos — it looks incredible on jackets, bags, hats, and even medical scrubs.

Step 5: Quality Control & Finishing

Every piece is inspected by hand. We check thread tension, alignment, and stitch density before it leaves the shop. Then we trim loose threads, steam-press garments, and package your order for shipping.

Our goal: a retail-quality finish that makes your brand shine.

PROMOXWEAR ships orders fast — typically within 7-10 business days — and we offer no minimums (small orders welcome).

🚚 Get started at PROMOXWEAR.com or call 813-550-3323 for a quick quote.

Why Businesses Love PROMOXWEAR

✔ Professional results – real proofing, perfect stitching, consistent branding

✔ Top apparel brands – Nike, Carhartt, Port Authority, Richardson, Flexfit & more

✔ Local service with nationwide shipping – from Tampa & Sarasota to all 50 states

✔ Personal attention – we care about every logo, big or small

From family-owned businesses to major contractors and corporate teams, companies trust PROMOXWEAR to make their logo stand out — beautifully, reliably, and affordably.

Final Thoughts

Every thread tells a story — of your business, your team, and your brand’s reputation.

At PROMOXWEAR, we don’t just embroider logos. We craft lasting impressions, one stitch at a time.

👉 Start your custom order today at PROMOXWEAR.com and let us turn your logo into art.